F-35 Aerospace Mixing Controls

At the F-35 Lightning II Joint Strike Fighter production facility in Fort Worth, TX, precision epoxy mixing is critical for the aircraft's innovative nanocomposite structures. The defense contractor faced significant challenges with their manual mixing system, achieving only 50% quality yield and incurring substantial material and labor losses. Our engineering team implemented a comprehensive digital solution utilizing Maple Systems PLC controls, which elevated production accuracy to 80% while enabling precise cycle control, data collection, and recipe management. This modernization significantly reduced operator error and enabled early detection of non-conformant mixtures, resulting in weekly labor savings of 30 hours and substantial cost reductions.

At the F-35 Lightning II Joint Strike Fighter production facility in Fort Worth, TX, precision epoxy mixing is critical for the aircraft's innovative nanocomposite structures. The defense contractor faced significant challenges with their manual mixing system, achieving only 50% quality yield and incurring substantial material and labor losses. Our engineering team implemented a comprehensive digital solution utilizing Maple Systems PLC controls, which elevated production accuracy to 80% while enabling precise cycle control, data collection, and recipe management. This modernization significantly reduced operator error and enabled early detection of non-conformant mixtures, resulting in weekly labor savings of 30 hours and substantial cost reductions.

The implementation required innovative solutions to overcome the PLC's inherent memory constraints and software limitations. Our team developed custom memory management protocols and devised efficient data structures to accommodate multiple recipes and extensive cycle histories within the system's limited retentive memory. We pioneered solutions for string data storage through ASCII code conversion and implemented FIFO registers for historical data management. Our technical expertise not only resolved the client's immediate challenges but also contributed to Maple Systems' software development, as our documentation helped identify and resolve multiple platform bugs. The system now maintains comprehensive production records with year-long data retention capabilities, accessible through standard spreadsheet applications.

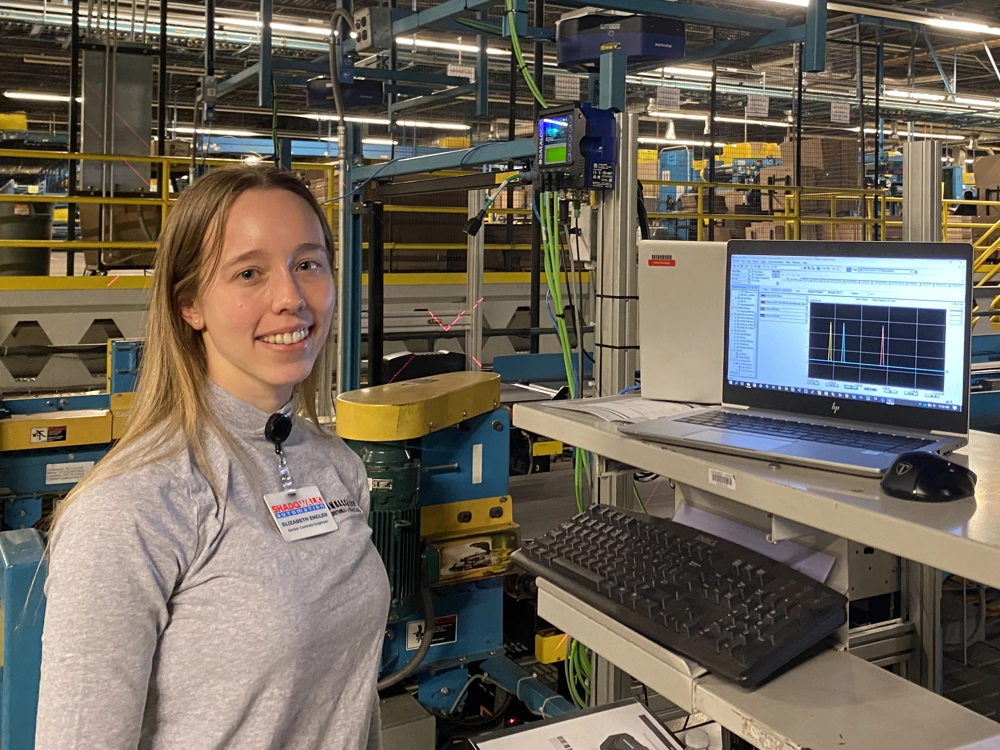

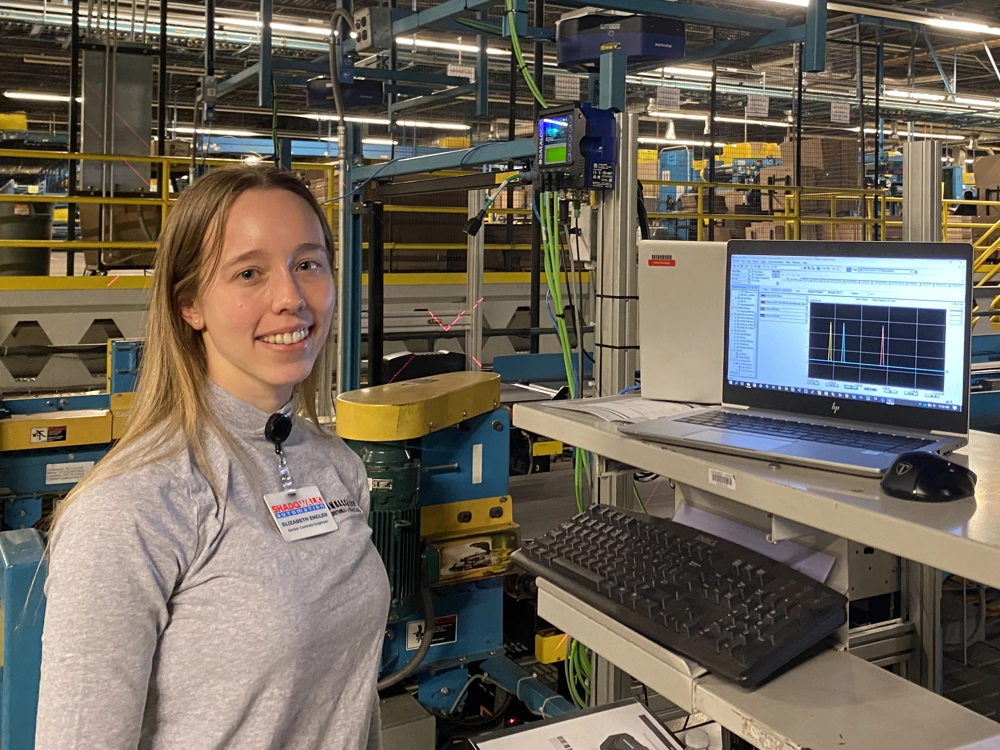

Barcode Scanner Migration & Upgrade

A major provider of distribution and logistics in Fort Worth, TX, contracted our engineers to program a series of barcode scanner upgrades. The previous system operated at an 80% success rate, with the new installation operating consistently above 98%. From the beginning, we created a sound installation strategy as we pre-wrote and tested code in a modular structure. Next, we installed the new scanners alongside the old and inserted our logic in a separate routine while the previous logic continued to run. We used add-on-instructions (AOIs) with a state-machine organization of steps, which handles data collection, handshakes, monitors statuses, and keeps a history of recent scans. This easy-to-troubleshoot style securely handles any process and is highly maintainable.

A major provider of distribution and logistics in Fort Worth, TX, contracted our engineers to program a series of barcode scanner upgrades. The previous system operated at an 80% success rate, with the new installation operating consistently above 98%. From the beginning, we created a sound installation strategy as we pre-wrote and tested code in a modular structure. Next, we installed the new scanners alongside the old and inserted our logic in a separate routine while the previous logic continued to run. We used add-on-instructions (AOIs) with a state-machine organization of steps, which handles data collection, handshakes, monitors statuses, and keeps a history of recent scans. This easy-to-troubleshoot style securely handles any process and is highly maintainable.

The converted barcodes are written to a critical plantwide data buffer. To seamlessly transfer writing responsibility between systems, we used an array of activation booleans to gradually switch each scanner over from old to new. The toggle function is a perk that allows our clients to keep and use the old scanners as backups. We not only successfully upgraded 100+ scanners, but included proficient tools for testing, troubleshooting, future adaptability, and ease of use. The new scanners included Cognex Dataman 260, Datalogic SC5000, Datalogic Matrix 120, and SICK CLV621. The upgrades were performed with zero downtime in just 2 days. We always aim to minimize or eliminate downtime, design efficient tools, and save our clients hours to get the most out of their systems.

High-Speed Yushin Gantry Automation

A leading eye care and optics manufacturer partnered with our engineering team to develop an automated cell for contact lens mold handling, inspection, and data collection. The project centered around programming a Yushin HST-250 gantry robot—a high-precision Japanese system rarely encountered in the industry—to execute sub-2-second cycles for mold extraction and placement. Our comprehensive scope encompassed PLC and robot programming, on-site commissioning, startup support, and FAT verification. The implementation featured sophisticated safety protocols, including DCS zones and interlock systems, while accommodating complex multi-robot coordination with a Fanuc SCARA system for quality sampling operations.

A leading eye care and optics manufacturer partnered with our engineering team to develop an automated cell for contact lens mold handling, inspection, and data collection. The project centered around programming a Yushin HST-250 gantry robot—a high-precision Japanese system rarely encountered in the industry—to execute sub-2-second cycles for mold extraction and placement. Our comprehensive scope encompassed PLC and robot programming, on-site commissioning, startup support, and FAT verification. The implementation featured sophisticated safety protocols, including DCS zones and interlock systems, while accommodating complex multi-robot coordination with a Fanuc SCARA system for quality sampling operations.

The project presented unique challenges due to our exclusive expertise with the Yushin platform and the demanding cycle time requirements. Through innovative programming approaches, including dual-axis diagonal movements and optimized transition points, we successfully achieved the required speed benchmarks. We addressed mechanical stability concerns at high velocities by implementing precise acceleration/deceleration profiles to prevent tooling degradation. The project concluded with detailed documentation of our Yushin robot implementation, establishing a valuable knowledge base for future maintenance and support activities.

At the F-35 Lightning II Joint Strike Fighter production facility in Fort Worth, TX, precision epoxy mixing is critical for the aircraft's innovative nanocomposite structures. The defense contractor faced significant challenges with their manual mixing system, achieving only 50% quality yield and incurring substantial material and labor losses. Our engineering team implemented a comprehensive digital solution utilizing Maple Systems PLC controls, which elevated production accuracy to 80% while enabling precise cycle control, data collection, and recipe management. This modernization significantly reduced operator error and enabled early detection of non-conformant mixtures, resulting in weekly labor savings of 30 hours and substantial cost reductions.

At the F-35 Lightning II Joint Strike Fighter production facility in Fort Worth, TX, precision epoxy mixing is critical for the aircraft's innovative nanocomposite structures. The defense contractor faced significant challenges with their manual mixing system, achieving only 50% quality yield and incurring substantial material and labor losses. Our engineering team implemented a comprehensive digital solution utilizing Maple Systems PLC controls, which elevated production accuracy to 80% while enabling precise cycle control, data collection, and recipe management. This modernization significantly reduced operator error and enabled early detection of non-conformant mixtures, resulting in weekly labor savings of 30 hours and substantial cost reductions. A major provider of distribution and logistics in Fort Worth, TX, contracted our engineers to program a series of barcode scanner upgrades. The previous system operated at an 80% success rate, with the new installation operating consistently above 98%. From the beginning, we created a sound installation strategy as we pre-wrote and tested code in a modular structure. Next, we installed the new scanners alongside the old and inserted our logic in a separate routine while the previous logic continued to run. We used add-on-instructions (AOIs) with a state-machine organization of steps, which handles data collection, handshakes, monitors statuses, and keeps a history of recent scans. This easy-to-troubleshoot style securely handles any process and is highly maintainable.

A major provider of distribution and logistics in Fort Worth, TX, contracted our engineers to program a series of barcode scanner upgrades. The previous system operated at an 80% success rate, with the new installation operating consistently above 98%. From the beginning, we created a sound installation strategy as we pre-wrote and tested code in a modular structure. Next, we installed the new scanners alongside the old and inserted our logic in a separate routine while the previous logic continued to run. We used add-on-instructions (AOIs) with a state-machine organization of steps, which handles data collection, handshakes, monitors statuses, and keeps a history of recent scans. This easy-to-troubleshoot style securely handles any process and is highly maintainable. A leading eye care and optics manufacturer partnered with our engineering team to develop an automated cell for contact lens mold handling, inspection, and data collection. The project centered around programming a Yushin HST-250 gantry robot—a high-precision Japanese system rarely encountered in the industry—to execute sub-2-second cycles for mold extraction and placement. Our comprehensive scope encompassed PLC and robot programming, on-site commissioning, startup support, and FAT verification. The implementation featured sophisticated safety protocols, including DCS zones and interlock systems, while accommodating complex multi-robot coordination with a Fanuc SCARA system for quality sampling operations.

A leading eye care and optics manufacturer partnered with our engineering team to develop an automated cell for contact lens mold handling, inspection, and data collection. The project centered around programming a Yushin HST-250 gantry robot—a high-precision Japanese system rarely encountered in the industry—to execute sub-2-second cycles for mold extraction and placement. Our comprehensive scope encompassed PLC and robot programming, on-site commissioning, startup support, and FAT verification. The implementation featured sophisticated safety protocols, including DCS zones and interlock systems, while accommodating complex multi-robot coordination with a Fanuc SCARA system for quality sampling operations.